We are proud that we, Bengar Industrial Corporation are the sole distributor of HITACHI Ink Jet Printer here in the country.

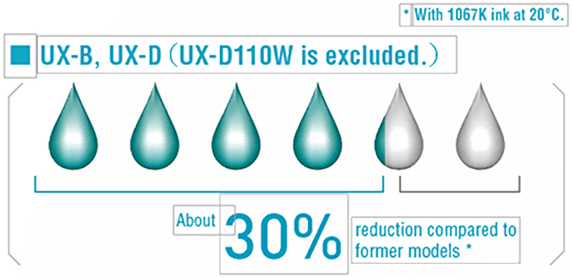

1. Makeup fluid consumption reduction system.

The ink recovery control and device temperature control provided by the new technology

of “Makeup fluid consumption reduction system” suppress the amount of makeup vapored and

achieve industry-leading levels of makeup consumption.

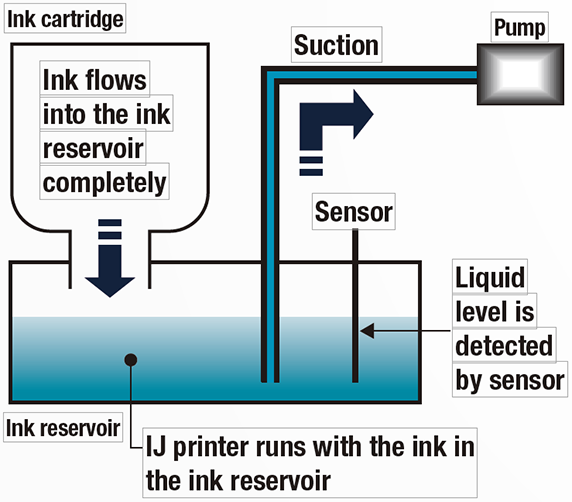

2. Eco-friendly

It is not necessary to stop the production line to replace the cartridges.

An eco-system of a simple cartridge-type bottle can be replaced after the

ink or makeup fluid is completely consumed and is also easily disposed of.

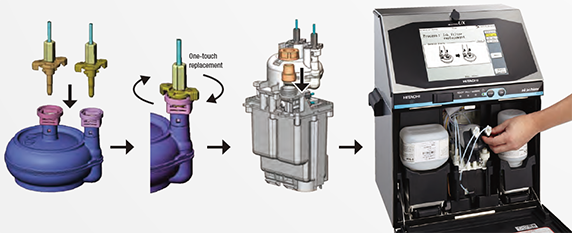

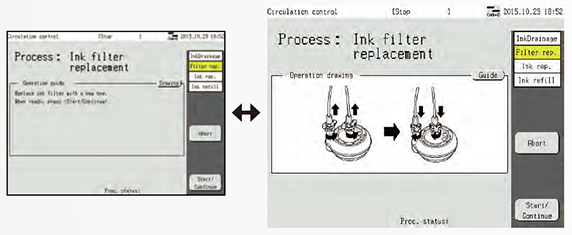

3. Filter replacement is so easy.

The IJ printer is so designed that the minimal part or module can be replaced rather

than replacing the whole unit. The ink filter can also be removed and replaced easily

without any tools just by rotating the joint.

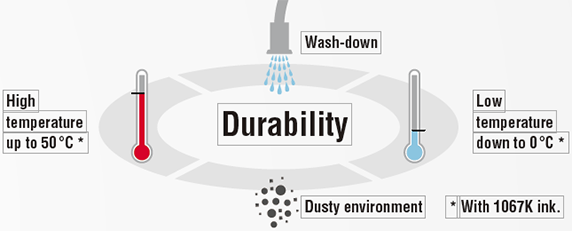

4. Designed for harsh evnironments.

The stainless steel cabinet offers IP65 and allows a wash-down with pressured water

and industrial detergent, to meet any environment and hygiene requests. The UX Series

with IP65 protection is the ideal choice for applications in the meat and dairy sectors.

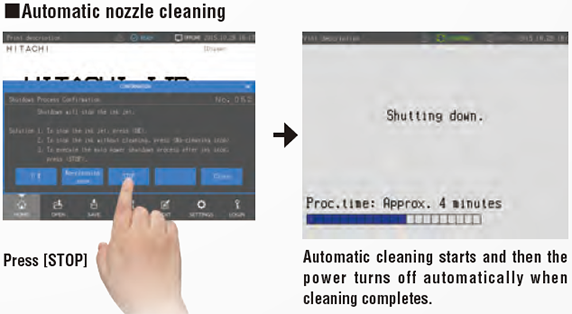

5. Automatic cleaning features.

Automatic cleaning starts by one press of a button and there is no need to wait for

its completion since the power turns off automatically when it is finished. Even if

the nozzle gets clogged, it can be easily recovered by the nozzle backwash function

that is opposite of the normal ink ejection, in which the fluid is sucked through the

nozzle.

6. User-friendly interface!

Intuitive operations with a new readily-understandable screen design is now adopted.

Most of the operations can be completed on one screen with a simplified and well-arranged

design. Complicated operations are not required to obtain the necessary information

thereby improving usability.

The necessary operations will be displayed on the screen using illustrations when the ink

filter needs replacement or when troubleshooting or maintenance is needed. Comprehensive

illustrations help to maintain the quality.

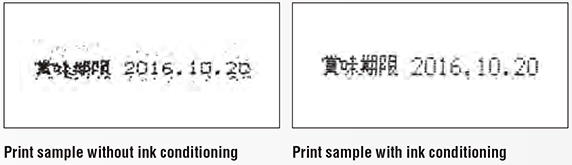

7. Ink conditioning management to maintain print quality.

By monitoring both the ink viscosity and the ink consumption, the ink viscosity is always k

ept in the best condition.

8. "6-line print" is available [For Twin Nozzle Model only].

6-line print from one printhead is made possible.

Even with multiple print lines, Hitachi original interlaced-print-control system makes each

printed character appear clearly. For single-line high-speed printing, its print quality is

improved with the new print control system.

Sample Prints:

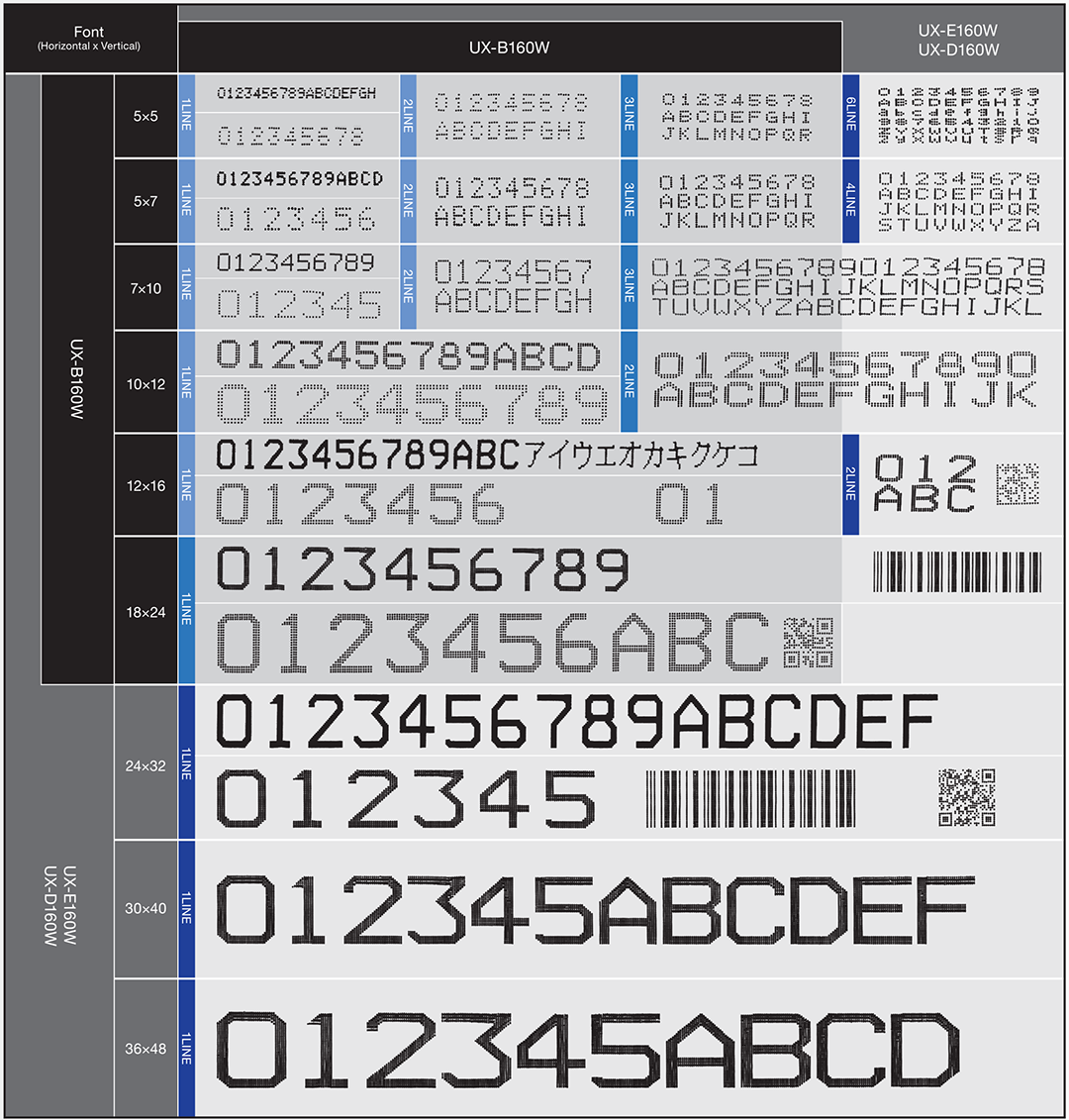

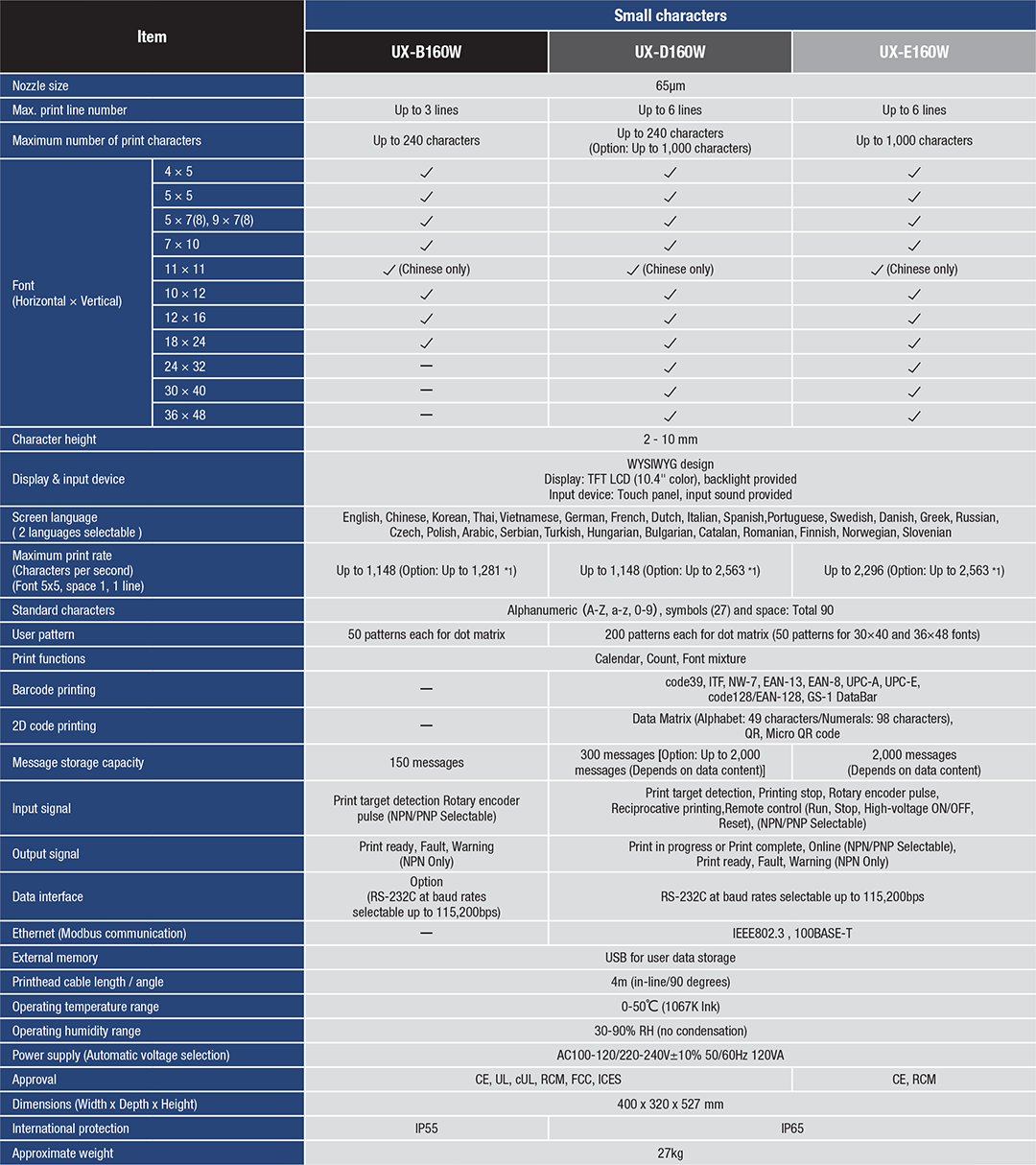

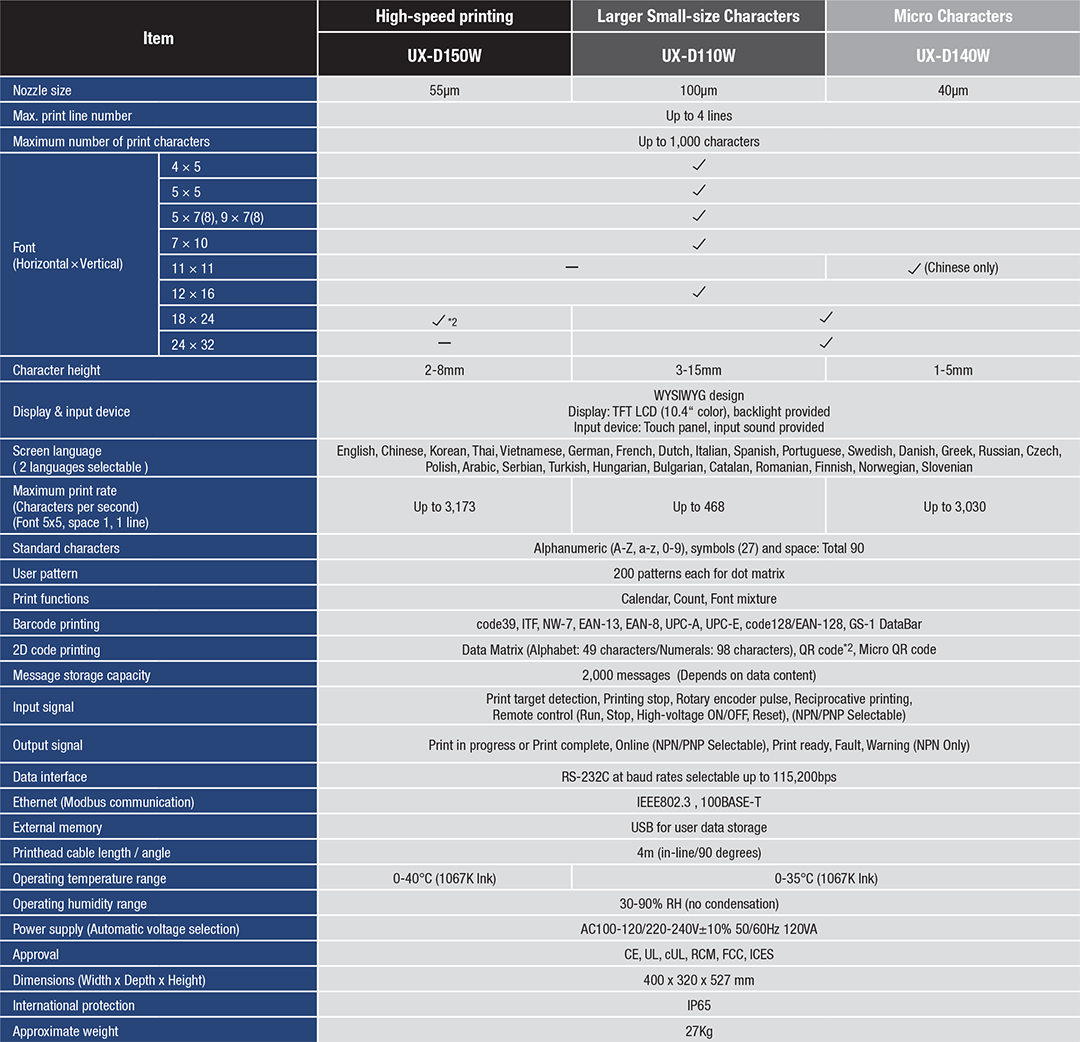

Printer Specs:

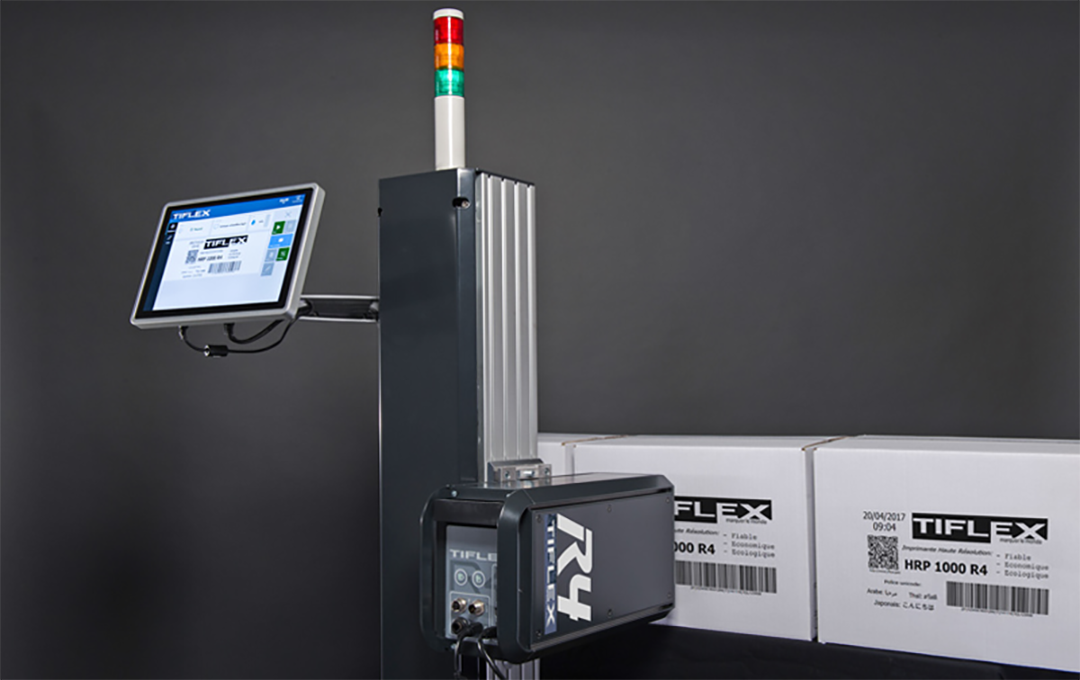

New Tiflex HRP R4 printer for marking secondary packaging, faster and more economical. HRP R4 is available in “gradient” mode thanks to its intelligent printing station, which can be controlled via a PC or tablet.

HRP R4 is designed to ensure the traceability of grouping units (cartons) in the agri-food, cosmetics, pharmaceutical and wood industry (pallets) sectors.

We have been certified by EPAL association for pallet inkjet marking. Feel free to contact our experts for more information.

Tiflex’s R&D teams have worked to propose numerous improvements on this new HRP R4 printer in order to meet the increasing demands of the market. HRP R4 is now available in umbilical version (remote head) !

Performance and speed

Printing up to 200 m/min at a height of 50 to 400 mm. Marking by side, top or inclined plane (thanks to umbilical version).

Key points

- 100mm print height

- More compact, easier to integrate on the production line.

- Greater head-to-carton distance for easier installation.

- 25% faster print head.

- 15% improved marking contrast, which guarantees perfect barcode printing.

- Marking cost 30% lower than the paper label.

- Ink supply by secure cartridges.

- Improvement of the OEE of the production line: no line stoppages (replacement of the ink without stopping the printer, 1 maintenance per year), networking possible.

- Dedicated, open and comprehensive Tiflex software solution (remote commands, data logging, printer status,…),

- new simplified user interface.

- Single to multiple printheads.

Areas of application

- Food

- Cosmetics

- Pharmaceutics Industry

- Packaging

Types of printing

- High-resolution barcodes

- 2D codes

- Texts

- Logos

Substrates

- Paper

- Carton

- Wood

- Textile